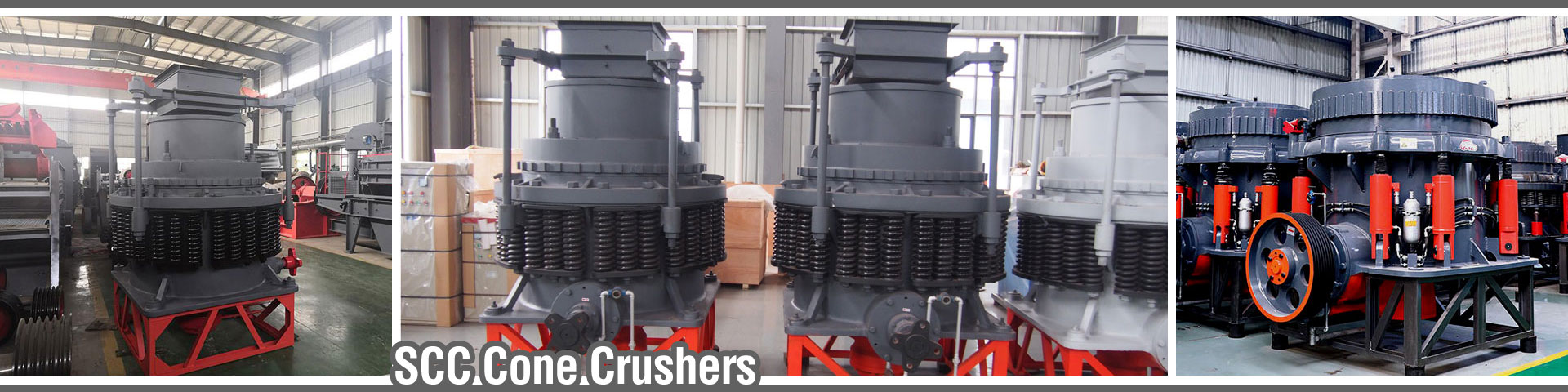

Cone Crushers

Cone crushers are the type of the cost effective crushers. Mainly cone crushers are used as the secondary crushers or third crushers. Cone crushers have the types of the spring cone crushers and hydraulic cone crushers.

- Outstanding structure with excellent operating cost and lower fault rate.

- Widely applying to crush kinds of raw material like granite, quartz, marble, river stone, etc.

- Reliable spring protection system can provide safety and efficient protection of overload

- Separate automatic oil lubrication system

- Low investment cost ,cost effective

A better low-cost and higher cost performance cone crushers. The work principle is that the cone squeeze the stone to crush them in different sizes.

* The structure will be different as customers’ requests.

Specifications

| Diameter of moving cone(mm) | Feeding open(mm) | Discharge opening (mm) | Capacity(TPH) | Weight (T) | Power (KW) | Overall dimensions (mm) |

|---|---|---|---|---|---|---|

| 600 | 65 | 12-25 | 40 | 5 | 30 | 2234*1370*1675 |

| 600 | 35 | 3-13 | 12-23 | 5.5 | 30 | 2234*1370*1675 |

| 900 | 115 | 15-50 | 50-90 | 11.2 | 55 | 2692*1640*2350 |

| 900 | 60 | 5-20 | 20-65 | 11.2 | 55 | 2692*1640*2350 |

| 900 | 40 | 3-13 | 15-50 | 11.3 | 55 | 2692*1640*2350 |

| 1200 | 145 | 20-50 | 110-168 | 24.7 | 110 | 2790*1878*2844 |

| 1200 | 100 | 8-16 | 42-135 | 25 | 110 | 2790*1878*2844 |

| 1200 | 50 | 3-15 | 18-105 | 25.3 | 110 | 2790*1878*2844 |

| 1750 | 215 | 25-50 | 180-360 | 50.3 | 160 | 3910*2894*3809 |

| 1750 | 185 | 10-30 | 80-210 | 50.3 | 160 | 3910*2894*3809 |

| 1750 | 85 | 5-15 | 60-180 | 50.2 | 160 | 3910*2894*3809 |

| 2200 | 300 | 30-60 | 420-700 | 90 | 280 | 4622*3302*4470 |

| 2200 | 230 | 10-30 | 130-410 | 80 | 280 | 4622*3302*4470 |

| 2200 | 100 | 5-16 | 80-200 | 81.4 | 280 | 4622*3302*4470 |

| Model | Cavity Type | Feeding open(mm) | Closed Side Feeding Size(mm) | Discharge opening (mm) | Power (KW) | Capacity(TPH) | Weight (T) |

|---|---|---|---|---|---|---|---|

| HP200 | C2 | 235 | 190 | 19 | 4P 160 | 90-250 | 10.4 |

| HP200 | M | 171 | 120 | 16 | 4P 160 | 90-250 | 10.4 |

| HP200 | F1 | 150 | 95 | 13 | 4P 160 | 90-250 | 10.4 |

| HP200 | F2 | 116 | 70 | 8 | 4P 160 | 90-250 | 10.4 |

| HP300 | C1 | 265 | 230 | 25 | 4P 220 | 115-440 | 18.1 |

| HP300 | C2 | 240 | 210 | 20 | 4P 220 | 115-440 | 18.1 |

| HP300 | M | 190 | 150 | 15 | 4P 220 | 115-440 | 18.1 |

| HP300 | F1 | 145 | 105 | 11 | 4P 220 | 115-440 | 18.1 |

| HP300 | F2 | 120 | 80 | 8 | 4P 220 | 115-440 | 18.1 |

| HP400 | C1 | 360 | 290 | 30 | 4P 315 | 140-630 | 25 |

| HP400 | C2 | 310 | 250 | 25 | 4P 315 | 140-630 | 25 |

| HP400 | M | 260 | 196 | 20 | 4P 315 | 140-630 | 25 |

| HP400 | F1 | 182 | 110 | 13 | 4P 315 | 140-630 | 25 |

| HP400 | F2 | 135 | 90 | 10 | 4P 315 | 140-630 | 25 |

| HP500 | C1 | 370 | 330 | 38 | 4P 400 | 175-790 | 36 |

| HP500 | C2 | 320 | 290 | 28 | 4P 400 | 175-790 | 36 |

| HP500 | M | 245 | 210 | 22 | 4P 400 | 175-790 | 36 |

| HP500 | F1 | 180 | 130 | 13 | 4P 400 | 175-790 | 36 |

| HP500 | F2 | 150 | 95 | 10 | 4P 400 | 175-790 | 36 |

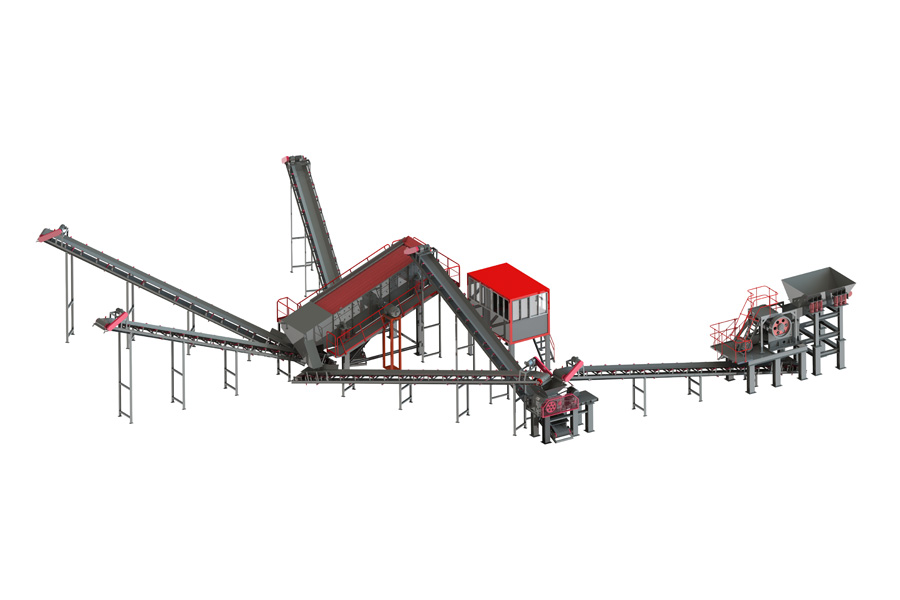

To see smarter runs on the work site

Options

| Options |

| Maintenance Platform |

| Mobile or portable structure |

| Diesel generator power |

| Structure customization |

| Control room |